Introduction

In today’s built-environment landscape, lighting design is no longer solely about visual comfort or aesthetics—it’s increasingly intertwined with energy efficiency, sustainability, and regulatory compliance. One of the key metrics that lighting engineers, architects, and building designers must grapple with is Lighting Power Density (LPD). In essence, LPD answers the question: how much electrical power is used for lighting per unit area of a space or building? By understanding “what is LPD in lighting” and “what is lighting power density,” one can design systems that not only meet visual and comfort requirements but also align with energy codes and long-term operational cost goals. In this article, I will unpack the concept of Lighting Power Density, explore its calculation, its role in codes and standards, compare common values across building types, and offer practical strategies for optimization. My goal is to provide a professional engineer’s viewpoint so you can confidently incorporate LPD into your lighting design process.

Defining Lighting Power Density: “What Is LPD in Lighting?”

When we ask “what is lighting power density,” we are referring to the metric that quantifies the electrical power consumed by lighting equipment per unit area of a particular space or building. Often abbreviated as LPD, this metric might also be expressed as watts per square foot (W/ft²) in U.S. customary units, or watts per square meter (W/m²) in metric systems.

What exactly does the term include?

In practice, Lighting Power Density includes not only the lamp or fixture wattage but all associated lighting loads — for example ballasts, drivers, transformers, controls, and other lighting-system components. If a driver is permanently connected and supports the lighting system, it must typically be included.

Why is LPD a key metric?

From an engineering standpoint, using LPD allows one to:

- • Compare design options for lighting systems based on power per area.

- • Check compliance with building energy codes or standards (which often define Lighting Power Allowances (LPA) tied to LPD values).

- • Provide a benchmark for energy-consumption modeling and long-term operational cost forecasting.

- • Drive sustainable and efficient lighting system designs—lower LPD means less power consumed for the same area (assuming specified light levels are maintained).

Methods of calculation

There are two prominent methods used for calculating LPD or applying it in design and code compliance:

- Building-Area Method: The total installed lighting power (in watts) is divided by the gross floor area of the building (in ft² or m²). This method gives a simple, aggregated value for the entire building.

- Space-by-Space Method: Here each distinct space type (e.g., open office, corridor, restroom, classroom) is treated individually, with its own LPD allowance. The sum of all spaces’ lighting loads divided by their individual areas yields the overall design compliance.

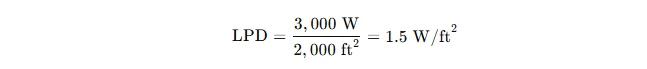

Example calculation

Suppose you have an open-plan office of 2,000 ft², in which the total lighting load (including fixtures, drivers, ballasts) is 3,000 W. Then:

LPD = 3,000 W / 2,000 ft² = 1.5 W/ft²

That would then be compared against the allowed LPD (or LPA) set by the applicable code or standard.

Relationship to Lighting Power Allowance (LPA)

It is helpful to understand that many codes or standards do not set an absolute desired LPD that designers should aim for—instead they define a maximum allowable lighting power density (commonly expressed as LPA) for a given space or building. In effect, designers must ensure that their actual LPD (the calculated or specified lighting power per area) does not exceed the LPA.

From my professional perspective, framing LPD as “what is lighting power density” allows a clear discussion with stakeholders: it becomes the metric that bridges lighting design, energy-use modelling, and compliance requirements. Rather than treating it as a secondary consideration, I argue for treating LPD up front as a design constraint—thus guiding fixture selection, layout, controls strategy, and lighting maintenance planning.

Why Lighting Power Density Matters: Significance, Code Compliance & Optimization

The significance of LPD in modern lighting design

Lighting systems are often one of the larger electrical loads in commercial, institutional, and industrial buildings. As such, optimizing lighting power density directly impacts a building’s energy consumption, operational cost, and carbon footprint. According to industry sources: “LPD is a fundamental consideration in lighting design because it directly affects both code compliance and the overall energy performance of a building.”

When I design lighting systems, I always emphasise that lowering LPD (while maintaining required illuminance, uniformity, and visual comfort) delivers benefits such as:

- • Reduced annual lighting energy consumption.

- • Lower peak electrical load (which can influence HVAC sizing due to latent heat from lighting).

- • Alignment with sustainability goals (e.g., achieving credits for building certifications like LEED).

- • Future-proofing against more stringent energy codes or utility incentives that fix lighting power allowances.

Energy codes and regulatory drivers

Many building energy codes (such as ASHRAE 90.1 and International Energy Conservation Code (IECC)) set maximum LPD limits for building types and space uses. For example, one document shows that the 2021 IECC defines interior lighting power allowances by building area method and space-by-space method.

Another point: older lighting technologies (e.g., inefficient fixtures, poor control strategies) often led to designs that exceeded allowable LPDs, making compliance difficult or costly. As one resource states, “If you use old, obsolete types of fixtures you may have trouble staying under the allowed LPD, while still meeting your light level goals.”

Comparison of typical LPD values

Here is a table summarising some illustrative LPD (maximum lighting power allowances) values drawn from the 2021 IECC (interior lighting) for selected building types.

And here is a second table illustrating typical values for some space-by-space allowances (for example purposes only):

From my engineering viewpoint, these tables help highlight that one cannot apply a “one size fits all” LPD target. Instead, you must consider space function, required light levels, ceiling height, geometry and control strategy—all of which influence the feasible LPD and whether you will easily comply with code.

Why focusing only on fixture efficacy is not enough

It might be tempting to assume that simply selecting high‐efficacy LED fixtures will automatically ensure a low LPD and compliance. While fixture efficiency is a significant factor, in my experience the following elements must also be addressed:

- • Lighting layout and fixture count: Over-lighting or too many fixtures can raise total wattage and thus LPD.

- • Controls and occupancy/daylight harvesting: Without good controls you may have excessive on-time and wattage, raising the effective LPD.

- • Room geometry and reflectance: Poor geometry or low reflectance surfaces can require higher installed power to meet light levels, increasing LPD.

- • Maintenance and depreciation factors: Over time, if lighting performance degrades, you may need to increase initial lux levels, thus more load—raising LPD or undermining designed margin.

From a personal opinion, I believe that a proactive design that targets LPD reduction from the early concept phase is far more cost-efficient (both initial cost and operational cost) than retrofitting later to fix non-compliance or high energy bills.

Strategies to optimise LPD

Here are some practical bullet-point strategies that I recommend to reduce LPD while ensuring lighting quality:

- • Maximise use of daylight and integrate daylight-responsive dimming.

- • Select high-efficacy luminaires (LEDs) with drivers, ballasts, and components optimised for low-wattage output for required illuminance.

- • Right-size the number of luminaires and focus lighting on task-areas rather than uniform over-lighting.

- • Use occupancy and vacancy sensors, time-schedules, and dimmers to reduce operational wattage.

- • Explore advanced lighting controls (e.g., DALI, networked control systems) to tailor lighting zones and adapt usage.

- • Simulate lighting early with room geometry, reflectance, and maintenance factors to ensure you don’t over-design.

- • Consider the “maintenance” and “future state” of the lighting system—use realistic depreciation factors and ensure the system remains under the LPD target over its life.

My professional view

In my role as a lighting engineer, I argue that LPD should be treated as a design constraint rather than merely a compliance checkbox. By placing LPD targets at the outset (e.g., aiming for 20% better than code), the design team is forced to think carefully about fixture selection, layout, controls, daylighting strategy, and future retrofit flexibility. This holistic approach results in lighting systems that are effective, energy-efficient, compliant, and sustainable long‐term.

Practical Application of Lighting Power Density: Calculation, Trade-offs & Case Study

Step-by-step calculation of LPD

To illustrate how to practically apply “what is lighting power density,” here is a structured process that I use:

- Define the area of the space (in ft² or m²) for which lighting design is being done.

- Determine the total installed lighting power (including fixtures, ballasts, drivers, transformers, etc) in watts for that space. Ensure you’re using worst-case or full load wattage unless controls have assured reduction.

- Compute LPD: LPD = Total Lighting Power (W) / Area (ft² or m²)

- Compare the calculated LPD against the applicable Lighting Power Allowance (LPA) from the building code or standard (using the correct method: building-area or space-by-space).

- If LPD exceeds LPA, design modifications are required—reduce wattage, reduce fixture count, incorporate controls, revise layout, or a combination thereof.

- Document the calculation and maintain margin—remember, performance can degrade over time, or usage may change, so building in buffer is best practice.

Trade-offs and real-world considerations

Incorporating LPD optimisation often requires balancing design aspects:

- • Lighting quality vs. power consumption: Sometimes to meet higher visual comfort levels (e.g., retail, healthcare) additional wattage is justified—but then the design must justify being near or above code.

- • Initial cost vs. operational savings: Higher upfront cost fixtures and controls often reduce total lighting load (thus lower LPD) and pay back via energy savings. I favour quantifying life-cycle cost early.

- • Flexibility for future changes: A lighting layout might change usage, so building in capacity may raise lighting load and LPD—design with modularity in mind.

- • Geometry and maintenance: Difficult-to-access fixtures, high ceilings, or complex geometry may require higher initial wattage to account for maintenance depreciation—thereby increasing LPD.

From my professional judgment, being conservative with LPD targets and auditing the lighting design holistically brings both compliance and value.

Case Study (hypothetical)

Consider a mid-sized corporate office building of 50,000 ft². The design team uses the building-area method and the code (say IECC 2021) gives an allowance of 0.64 W/ft² for “Office” use.

- • The design lighting specified totals 30,000 W for the lighting system.

- • Compute LPD: 30,000 W / 50,000 ft² = 0.60 W/ft².

- • Because 0.60 W/ft² is below 0.64 W/ft², the lighting design is within allowance.

But the team decides to aim for a 20 % reduction below allowance to improve sustainability credentials. This means targeting ≈0.51 W/ft² (0.64 ×0.80). They revise fixture specs, reduce fixture count via more efficient light distribution, and add daylight + occupancy controls. Resulting design: 25,500 W total lighting load → LPD = 25,500 / 50,000 = 0.51 W/ft².

This revision not only satisfies code but gives a meaningful efficiency improvement. Long-term energy savings are estimated, payback calculated, and lighting quality verified via simulation.

From my experience, implementing a case like this early avoids expensive retrofits and builds resilience against future code tightening.

Comparison table: Traditional vs. Optimised lighting design

This simple comparison demonstrates how optimising LPD contributes value—not merely compliance.

My viewpoint on future trends

Looking ahead, I believe that LPD will continue to gain importance as energy codes become more stringent, as the focus on carbon‐reduction intensifies, and as lighting controls and IoT integration become more pervasive. Designers and engineers who treat “what is LPD in lighting” as a core metric will have a competitive advantage—providing systems that are efficient, flexible, and aligned with sustainability goals. Moreover, I expect increased adoption of metrics beyond static LPD—incorporating actual usage hours, dimming reduction, and dynamic controls—to refine the effective lighting power density in real operation.

Conclusion

In summary, Lighting Power Density (LPD) is a vital metric that answers “what is lighting power density” and “what is LPD in lighting”. It quantifies the installed lighting power per unit area, allowing designers to benchmark, model, and ensure compliance with energy codes and best practices. By treating LPD proactively—using the calculation methods, comparing against allowances, and optimising design early—engineers can deliver lighting systems that are visually effective, energy efficient, and future-proof. From fixture selection and layout decisions to controls strategy and daylight integration, many levers influence LPD—but the core concept remains the same: lower lighting power per area (while satisfying lighting requirements) equals better performance. As an engineer, I believe the focus on LPD is not merely a regulatory hurdle—it is an opportunity for improved design, operational savings, and sustainability leadership.