PCBA One-Stop Service

PCBA One-Stop Electronics Manufacturing Service

One-stop PCBA service

DFM Design for Manufacturability

Issues that come up during product design and manufacturing can be identified and addressed before they become major problems.

PCB production

Offer proofing and batch services based on PCB board documents and process requirements supplied by customers.

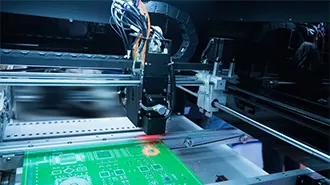

SMT patch processing

Shenzhen’s 3,000-square-meter production facility features multiple SMT and plug-in lines, offering customers high-end SMT patch processing services.

Component procurement

We provide BOM component orders. We source our products from original manufacturers and first-tier distributors, ensuring authenticity. With over 10 years of industry experience, we rigorously implement IQC incoming material inspections.

Finished product assembly

Equipped with assembly lines, scientific workstation design and management, and strict control of production efficiency.

Programming test

We manufacture FCT test fixtures based on the test points, procedures, and test steps designed by customers, and provide programming and FCT testing services.

High-Temperature Burn-in Testing

Equipped with high temperature aging room, it can provide batch aging conditions up to 80℃.

Conformal coating

Equipped with a fully automatic coating production line to perform conformal coating and infrared curing for PCBA

High-quality supply chain system starts with the quality of components

With over 18 years of industry experience, our senior supply chain management team provides full BOM material supply, device selection, and alternative material recommendations. We are equipped with professional BOM engineers and strict, standardized 10C incoming material inspection standards. We also guarantee genuine products from original manufacturers and first-tier agents. We use a constant temperature and humidity, anti-static, and first-in-first-out control mechanism in our component warehouses to ensure that we provide customers with components with short delivery times, good quality, and low prices.

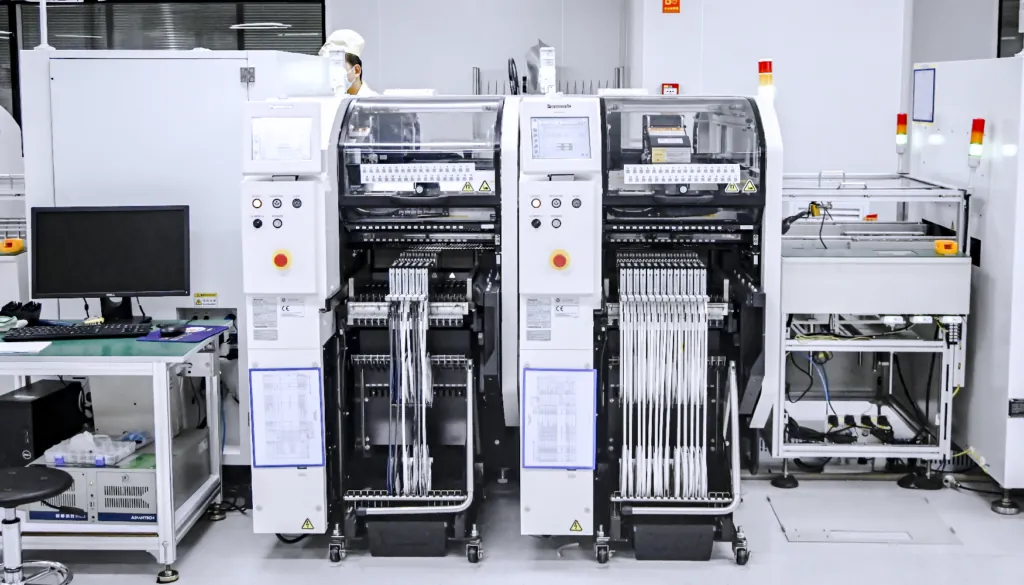

International-standard production equipment meets high-precision production requirements

In order to provide customers with the best quality products and services, our factory has set up a million-level dust-free production workshop, equipped with Panasonic imported high-speed dual-track patch line, fully automatic tin blue printing machine, xenon reflow oven, wave soldering, A0, SP, XRAY, intelligent first-article inspection instrument, intelligent tin management cabinet, fully automatic board separation machine, three-proof paint automatic coating, laser engraving machine, BGA rework station and other equipment, and is equipped with MES intelligent management system, intelligent warehousing system, ERP system and electrostatic management system.

Fully automatic solder paste printing machine

Fully automatic solder paste inspector (3D SPI)

NPM-D3A

NPM-TT2

AOI

Ten-zone nitrogen reflow oven

Sample Testing

X-ray

Laser engraving machine

Wave Soldering Furnace

Automatic board separator

Three-proof paint automatic coating line

Design capabilities

With exceptional ODM (Original Design Manufacturing) capabilities, customers can personalize and design unique products to carve out a niche in their specific market. Our team of designers and engineers can bring their ideas to life, from initial concept development to finished product, while ensuring exceptional quality and timely delivery.

Electronic design

Industrial Design

Mechanical Design

Software Design

Interface screen printing

Equipment logo

Boot logo

Packaging customization